Voltmeters, ammeters, ohmmeters or, as a "compact device", multimeters are the ultimate life-savers or at least good-mood savers if the circuit you have built yourself does not work.

Sometimes it happens that even though you have followed a detailed construction plan, the built circuit still does not work. At the latest then one sits after the initially motivated work very often very frustrated in front of the built circuit and would like to throw everything back.

In such situations, good advice is often expensive. In order to give you a little guide on how you can possibly at least get on the track of the problem in these situations, here comes the following article.

These small, compact devices can be used to measure various electrical variables and thus quickly localize faults.

Safety instructions

I know the following notes are always kind of annoying and seem unnecessary. Unfortunately, many people who knew "better" have lost eyes, fingers or other things due to carelessness or injured themselves. Data loss is almost negligible in comparison, but even these can be really annoying. Therefore, please take five minutes to read the safety instructions. Because even the coolest project is not worth injury or other trouble.

https://www.nerdiy.de/sicherheitshinweise/

Affiliate links/advertising links

The links to online shops listed here are so-called affiliate links. If you click on such an affiliate link and make a purchase via this link, Nerdiy.de will receive a commission from the relevant online shop or provider. The price does not change for you. If you make your purchases via these links, you support Nerdiy.de in being able to offer other useful projects in the future. 🙂

Requirements

Helpful articles:

Not really a requirement but an example of a practical application can be found in the article Electronics - Commissioning of a new circuit

Required material:

-no-

Required tool:

In the following list you will find all the tools you need to implement this article.

The functions of a multimeter

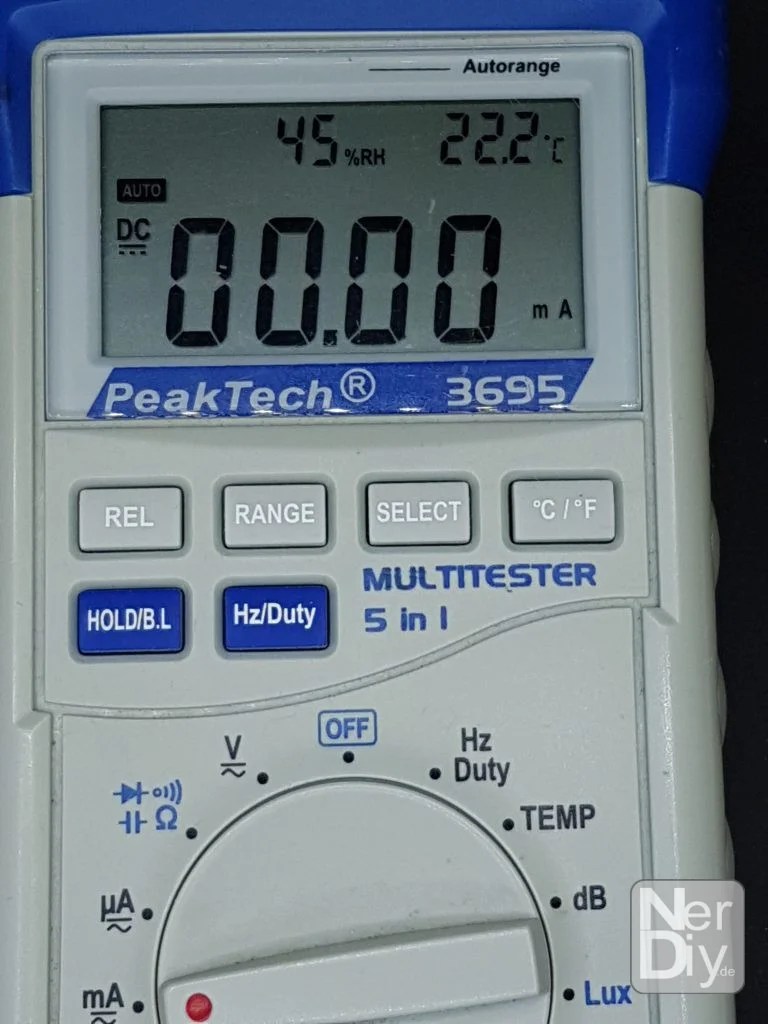

It is important for later troubleshooting to know and be able to use the basic functions of a multimeter. This is not always easy, because modern multimeters are often equipped with all kinds of functions. To give you an overview of the individual functions, they are described in the following sections.

Measuring range selector switch

The measuring range selector switch is the main control element of your measuring device. This roughly determines which quantity you want to measure. For some measuring ranges, such as "Hz/Duty", you can switch between the options using the buttons. To set the measuring range selector switch to the desired option, turn it so that it points like a pointer to the desired measuring range.

Button

The buttons available on a measuring device often vary from model to model. In most cases, there is only a "measuring range selector switch" with which you can select the electrical quantity to be measured.

In some models, however, additional functions can be selected via the pushbuttons. As an example, the functions of the pushbuttons of the measuring device shown are therefore described.

With the "HOLD/B.L" button you can "hold" the measured value that is displayed on the screen at the time the button is pressed. The displayed measured value therefore remains on the screen and you have enough time, for example, to note down the corresponding value at your leisure. A long press on this button also switches off the background lighting (BackLight) to enable or disable.

The Range key allows you to adjust the measuring range manually. With many measuring devices, this measuring range is now determined automatically. Nevertheless, it may sometimes be necessary to be able to set this measuring range manually. For this reason, it is always important - especially when measuring current and voltage - to be aware of the "rough" order of magnitude of the electrical quantity to be measured before starting the measurement. For example, if you only want to measure 12V, you need to take completely different safety precautions than when measuring 500V or more. Be sure to observe the safety instructions!

The "°C/°F button" allows you to change the unit of temperature measurement between Celsius and Fahrenheit. Fahrenheit is the most common unit in the United States. Celsius is the unit of measurement in all other countries.

You can use the "Hz/Duty" button to switch between the frequency and duty cycle measurements. As these two measured variables share a setting position on the measuring range selector switch, it is possible to switch between them.

The "REL" button allows you to set a new "zero point" for subsequent measurements. For example, you can compare two voltages. For example, if you measure a voltage of 5V during the first measurement and then press the "REL" button, all subsequent voltages will be measured in relation to the first. For example, if you measure a voltage of 8V after pressing the "REL" button, only 3V will be shown on the display of your measuring device because 5V is used as a reference for this measurement.

With the help of the "Select" button you can select whether you want to measure an AC variable (=AC) or a DC variable (=DC). For example, if you want to measure the DC voltage of a battery or rechargeable battery, it is important that you set both the measuring range selector switch to "V" (=voltage measurement) and the type of variable to DC voltage (=DC). If, on the other hand, you want to measure the voltage of a socket, you must set the type of variable to AC voltage (=AC).

Connection sockets:

There are four connection sockets in the lower area into which the test leads can be plugged. The "most important" one is the "COM" socket. The black lead always remains plugged in. Only the red test lead is reconnected depending on which electrical quantity is to be measured.

For example, if you want to measure a current with a magnitude in the ampere range, you have to connect the red measuring lead to the socket "10A" plug in. It is also important to note that the designation "10A" indicates that this connection is fused with "only" 10A. This means that higher currents cannot be measured directly. If you do not measure any current at all when using this socket, this fuse is most likely defective. How you can replace it is described in the operating instructions for your measuring device.

Right next to the "10A" socket you will find the "TEMP/µA/mA" socket. You must plug the red test lead into this socket if you want to measure currents in the mA and µA range - i.e. less than 1A. This socket is also protected by a fuse. In many cases, however, as in this case, it is protected by a self-resetting fuse. An external temperature sensor can also be connected to this socket on this measuring device. Hence the "TEMP..." in the socket name.

The last socket is located on the right side of the meter shown. This with a Capacitor, diode, voltage, resistor symbol and "Hz" marked socket is needed for all other measurements. So if you want to measure capacitances, resistances, voltages or frequencies, you have to use this socket. Also for the diode test - to determine the forward direction and forward voltage of a diode - you must use this socket.

Voltage measurement

One of the important electrical quantities is voltage. It can be measured relatively easily with a multimeter.

Nevertheless, you should think about the expected voltage beforehand. Because the precautionary measures during the measurement must also be adapted to this. It is not only important to know which voltage value you should expect but also which voltage type. So whether alternating voltage (AC=alternating current) or direct voltage (DC=dc voltage).

Here is a small quote from the very detailed Wikipedia article (https://de.wikipedia.org/wiki/Ber%C3%BChrungsspannung):

In healthy adult humans, one goes with the crossing of the Extra-low voltage from 50 V Alternating current (AC) or 120 V direct current (DC) from a life-threatening situation.[3] Among other things, for children and larger farm animals, the touch voltage is only set to a maximum of 25 V AC or 60 V DC, in wet roomInstallations partly even to 12 V.

This means that you can normally measure voltages up to at least 25V AC and 60V DC without any great risk to your life. If you are not a "professional", you should generally avoid working with higher voltages (it is often not necessary).

To measure the voltage with a multimeter, you must first set it to the voltage measurement range. This is usually marked with a "V" for volt (i.e. the unit of electrical voltage). Unfortunately, the correct setting here is not standardized and differs for many measuring devices. If you want to be absolutely sure, take a look at the operating instructions for your measuring device.

Once you have set the voltage measurement, it is now important that you set the voltage type. In the example meter, the voltage is set using the "Select" button. Unfortunately, this is not the same for all measuring devices.

For the actual voltage measurement, the measuring tips are then always connected in parallel to the consumer or generator whose voltage you want to measure.

It is important to know that a measuring device in the voltage measurement has a very high but measurable internal resistance. During the voltage measurement, you therefore inevitably connect a resistor in parallel to your consumer to be measured, which creates a parallel circuit of two resistors and thus a (slightly) higher current flows through the overall circuit. This may also cause the voltage to be measured to be slightly lower than it would be without the meter. This is negligible in most cases but still good to have in mind 🙂 .

Current measurement

The current is another important electrical quantity. It can also be measured quite easily with a multimeter. In contrast to the voltage, however, the circuit whose current is to be measured must be somewhat prepared and estimated.

Resistance measurement

Resistance measurement is actually a combination of voltage and current measurement. However, since resistance is also one of the important electrical quantities, its measurement is possible directly with many measuring devices.

Actually, the resistance of a circuit is (simplified) the proportionality constant of voltage to current. That is, the resistance indicates how much current flows through a circuit at a certain applied voltage. This means that if you know what voltage is applied to a circuit and then also know what current flows through the circuit at this voltage, you can easily calculate the resistance.

Continuity test

The continuity test is actually a luxury version of the resistance measurement. It can be used to determine very easily whether two contacts are electrically connected.

If, for example, you want to check whether you have correctly implemented your circuit from the circuit diagram into reality, you can use the continuity test to measure whether the contacts that should be electrically connected according to the circuit diagram are actually connected. You can find out whether two contacts are electrically connected by touching the first contact with the black measuring tip and the second contact with the red measuring tip. If both contacts are connected, the meter usually signals this with a beep and the resistance value shown in the display. Whether two contacts are connected is determined with the resistance measurement. If the resistance from one contact to the other is very low, there is also a connection between them.

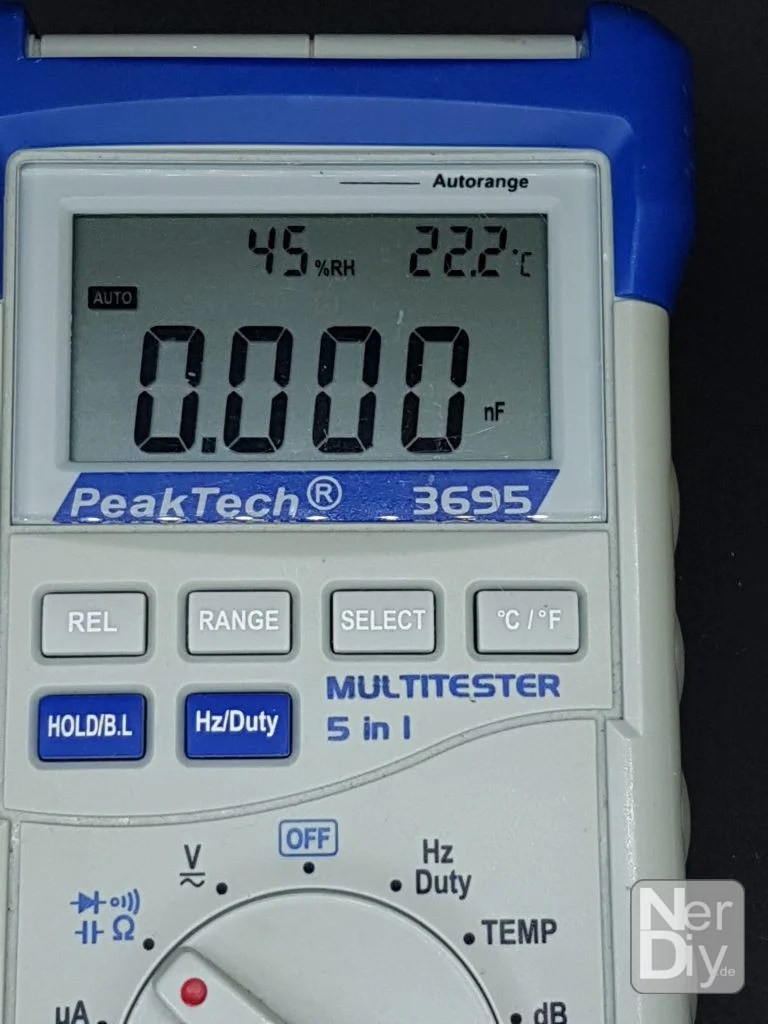

Capacitance measurement

The capacitance measurement allows you to determine the capacitance of a capacitor. This is especially helpful if you find a capacitor in your component drawer whose value is no longer clearly readable.

To measure the capacitance, simply hold the measuring tips of the meter against the two contacts of the capacitor.

Diode test

With the help of the diode test you can determine the forward direction and the forward voltage of a diode. This is especially helpful with SMD diodes, because the forward direction is not always printed on the package.

You can recognize the forward direction by holding the measuring tips to the two contacts and trying out in which combination a voltage is shown on the display. For example, if you hold the red measuring tip to the first contact of the diode and the black measuring tip to the second contact and you then see a voltage on the display, you know that the contact to which you have just held the red measuring tip is the anode of the diode.

The displayed voltage is then the forward voltage of the diode. If, on the other hand, no voltage is displayed, you must reverse the measurement tip assignment. In this case you have only found the reverse direction of the diode.

Frequency measurement/duty cycle

The frequency or duty cycle measurement is not integrated in all measuring instruments. With the help of these you can measure frequencies of an AC voltage or the duty cycle of a switched DC voltage.

For example, it is also relatively easy to check whether a pulse width modulation you have programmed works.

Possible additional functions

Temperature

Some meters also have the option of measuring temperatures with the aid of an externally connected thermocouple. To do this, you must connect it and set the meter accordingly.

dB

With the help of the dB measurement you can measure the sound pressure of a sound.

Lux

With the help of illuminance measurement you can measure the illuminance in a room.

x10Lux

In order to be able to measure very high illuminance levels - for example in strong sunshine - you can switch the sensitivity of the illumination measurement. This means that you can measure higher illuminance levels or show them on the display.

Troubleshooting

Now to the actual troubleshooting. It is difficult to provide an exact, universally valid "timetable" that always works. Unfortunately, faults are often hidden where you don't expect them.

However, many errors are simply careless mistakes. These can usually be found very quickly with the following roadmap.

- Continuity test of all connections in the de-energized - i.e. switched off - state.

- Check that all connections that should exist according to the circuit diagram are actually connected. The continuity test is perfect for this.

- You can also check that neighboring contacts on the board have not been accidentally short-circuited.

- Especially the power supply lines should not have a short circuit. You can also test this with the continuity test. The measuring device should then show no continuity.

- Check installed resistors for correct value.

- To do this, measure the installed resistors in a de-energized state.

- In case of deviating values, please note that the respective resistor could also be connected in parallel with other resistors, which would change its value. In case of doubt you have to disconnect one contact of the resistor from the circuit and measure the resistor separately.

- Check power supply and other voltages

- It is often helpful to check the individual supply voltages. If you have several supply voltages in your circuit (e.g. 3.3V and 5V) you should make sure that both are available and that they do not drop under load.

- Check input current.

- By checking the input current, you can easily determine whether there is a short circuit or a missing connection, for example.

- If the current is very high, you will most likely have built in a short circuit. Then look for a connection between the positive and negative contact of the power supply of your circuit.

- If the current is very low, it is possible that you have forgotten to connect the power supply. It could also be that a voltage regulator is defective. If you use a microcontroller, it could be that it is held in reset mode by a faulty circuit.

- Check the voltage of the logic levels.

- Especially for digital communication between a microcontroller and connected sensors it is important that they use the same logic levels. For example, a microcontroller that works with 1.8V logic levels will not work well with a sensor that expects 5V logic levels. This can be solved by measuring the voltages and/or looking at the data sheets of the devices involved.

Step-by-step structure to avoid/detect errors directly

Admittedly, this is a bad tip for troubleshooting after the complete circuit is already built. But maybe it will help you to build your next circuit:

For very complex circuits or circuits with several sensors, actuators, etc., it is advisable to put them into operation "step by step". This means that you first check that the microcontroller works without connected sensors and is programmable.

If this works, the next sensor is connected and checked again whether it works. If everything works, the next sensor/actuator is connected. Continue this until all circuit parts are built.

If after a newly added component this or something or even the complete circuit does not work anymore, you already have an approach for troubleshooting. You can then be quite sure that the newly added component has something to do with the error or is the cause of it.

In this case, you can remove the added component again as a kind of "cross-check". If the error no longer occurs in this case, you have confirmation that the error is related to the corresponding component.

In this case, it is then necessary to find out why this component is causing the error?

- Is it perhaps defective? If available, try to install and test another copy of the corresponding component.

- To what extent does the current consumption of your circuit change when the component is installed? Is it possibly so high that there are no longer enough power reserves available to supply the entire circuit? Here you should check whether the supply voltages "collapse"/drop by measuring the voltage.

- With sensors/actuators that communicate via the I2C/IIC or other buses, it may be that the other bus participant interferes with the communication. Check here possibly existing terminating resistors, PullUps and short circuits. Keep in mind that especially with the I2C bus a further bus participant increases the bus capacity and therefore the PullUps must be adapted.

The advantage of this "procedure" is that you have a direct idea of what could have caused the error. This makes troubleshooting easier and the error will hopefully be rectified more quickly.

Further information

https://de.wikipedia.org/wiki/Ber%C3%BChrungsspannung

Have fun with the project

I hope everything worked as described for you. If not or you have questions or suggestions please let me know in the comments. I will then add this to the article if necessary.

Ideas for new projects are always welcome. 🙂

PS Many of these projects - especially the hardware projects - cost a lot of time and money. Of course I do this because I enjoy it, but if you think it's cool that I share the information with you, I would be happy about a small donation to the coffee fund. 🙂

Thank you for your always very detailed and interesting articles!

Good luck with your future projects

Thanks very much. 🙂